Lorsque les gens parlent de sacs EVA, ils pensent toujours à un sac d’emballage en plastique fabriqué en EVA.

Mais aujourd’hui, nous allons vous présenter un produit innovant :

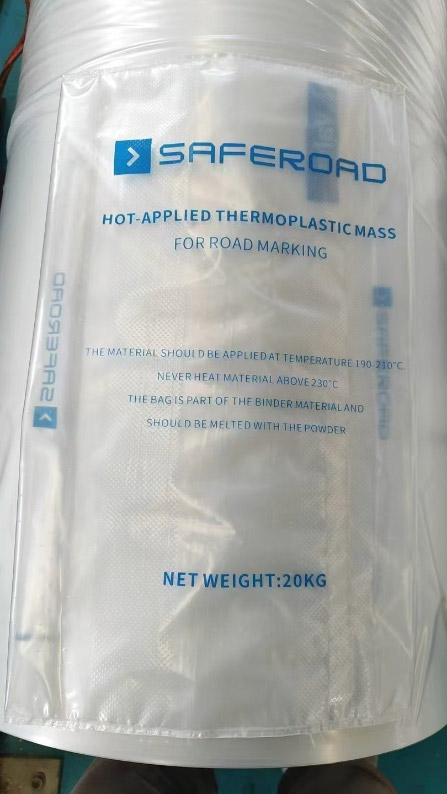

Sacs à valve EVA

.

Que sont les sacs EVA Value ?

Les sacs à valve double couche en EVA (éthylène-acétate de vinyle) ne sont pas des matériaux d'emballage. Il s'agit d'un additif filmogène utilisé pour les revêtements thermofusibles utilisés dans le marquage routier.

Pourquoi choisir les sacs EVA Value ?

Après avoir mélangé et fait fondre 2,5 kg de sacs à valve EVA avec 1 tonne de revêtement thermofusible, des effets significatifs seront exercés sur la résistance à la compression, l'adhérence des billes de verre, la résistance aux fissures et la résistance aux intempéries du revêtement de marquage.

Paramètres du sac à valve EVA :

| Autres noms | Masse thermoplastique appliquée à chaud |

| Caractéristiques | Sacs de valeur en EVA à double couche |

| Matériel | EVA+PE |

| Longueur | 610 ± 10 mm |

| Largeur | 350 ± 10 mm |

| Point de fusion | 100±5℃ |

| Épaisseur d'une seule couche | 6,0 s ± 0,5 s |

| Poids | 63±5g |

Voici une analyse détaillée élément par élément :

1. Impact sur la résistance à la compression (conditions inférieures à 60 °C)

Exigences de JT/T280-2022 : La résistance à la compression à 60℃ doit être ≥2MPa.

- Pour les revêtements thermofusibles à haute résistance à la compression, les lignes de marquage formées sont sujettes aux fissures. L'ajout de sacs d'emballage souples améliore considérablement la résistance du revêtement aux fissures.

- Effet adoucissant des sacs en film flexible EVA : avec un point de fusion bas et une certaine flexibilité même à -20℃, ils réduiront la rigidité globale du revêtement thermofusible.

- Réduction de la résistance à la compression : les revêtements thermofusibles traditionnels (résine de pétrole + charge) ont une rigidité élevée (≥ 2 MPa) à 60 ℃, mais après l'ajout de 40 sacs à valve double couche, la flexibilité du revêtement de marquage est améliorée.

2. Impact sur l'adhérence des billes de verre

- Amélioration de l'adhérence des sacs à valve EVA :

- Mouillabilité à l'état fondu améliorée : après la fusion, le film flexible a une bonne fluidité, ce qui peut mieux envelopper les billes de verre et améliorer la force de liaison.

- Tampon élastique pour réduire la perte : L'allongement élevé à la rupture des sacs en film flexible leur permet de subir une déformation élastique sous les charges de trafic, réduisant ainsi le risque de perte de billes de verre due à un impact.

- Effets pratiques :

- Le taux d'adhérence des billes de verre est augmenté et leur résistance aux chocs est renforcée, retardant l'atténuation du coefficient de luminosité rétroréfléchissant des lignes de marquage.

- La durabilité à long terme est améliorée, avec un taux de rétention plus élevé des billes de verre sous des charges dynamiques, prolongeant la durée de vie réfléchissante des lignes de marquage.

3. Impact sur la résistance aux fissures

- Effet durcissant des sacs en film souple :

- Capacité de dispersion des contraintes améliorée : l'allongement élevé des sacs en film flexible à double couche leur permet d'absorber les contraintes causées par le rétrécissement de la surface de la route ou les vibrations de la circulation, réduisant ainsi la propagation des fissures.

- Résistance améliorée aux fissures à basse température : en dessous de -20 ℃, les sacs en film flexible à double couche conservent leur flexibilité, réduisant ainsi le risque de fissures de fragilisation à basse température.

- Effets pratiques :

Le taux de fissuration des nouvelles lignes de marquage thermofusible standard est réduit. Comparé au système à base de résine de pétrole pure, le risque de fissuration peut être réduit de 30 à 50 %.

- Le nombre de micro-fissures est réduit, la surface des lignes de marquage est plus lisse et le problème de pelage causé par les fissures est réduit.

4. Impact sur la résistance du revêtement aux intempéries

- Caractéristiques de résistance aux intempéries des sacs en film flexible à double couche :

- Résistance aux UV : les matières premières des sacs en film flexible à double couche sont constituées d'EVA + modificateurs, qui peuvent réduire efficacement le jaunissement et le poudrage du revêtement de marquage sous une irradiation ultraviolette à long terme.

- Résistance à l'humidité et à la chaleur : les sacs en film flexible à double couche ont un taux d'absorption d'humidité extrêmement faible et n'affectent pas la durabilité à long terme dans les environnements à haute température et à forte humidité.

5. Résumé des impacts globaux

L'ajout de sacs d'emballage de qualité film EVA (40 sacs, environ 2,5 kg de colle flexible ajoutés à 1 tonne de revêtement) peut réduire la fragilité des lignes de marquage thermofusible et améliorer considérablement l'adhérence des billes de verre, la résistance aux fissures, la ténacité à basse température et la résistance aux intempéries.

Les sacs flexibles à valve EVA double couche de qualité film peuvent devenir une solution économique et efficace pour améliorer les performances globales des lignes de marquage thermofusible.