La technologie de tannage du cuir à la zéolite est lancée et présentée pour la première fois au 104e Tokyo Leather Show au Japon !

En repensant à la 104e Foire du cuir de Tokyo en mai 2024, elle est encore fraîche dans ma mémoire. Ce salon du cuir s'adresse principalement aux clients des secteurs du luxe et de la mode. L’industrie mondiale du cuir se rassemble. Ces entreprises, marques et institutions représentent des tanneurs et des fabricants d'accessoires, de composants, de tissus et de matériaux synthétiques, au service de l'ensemble des industries manufacturières du luxe, de la mode, du design, de l'automobile et de l'ameublement.

Département marketing iSuoChem / Edité par Jason

Salon du cuir de Tokyo 2024

Une variété de produits en cuir, à la pointe de la qualité et des performances, de la durabilité et de la praticité, sont entièrement basés sur les normes les plus élevées. Parmi eux, la technologie de tannage du cuir à la zéolite, utilisée pour résoudre le problème de pollution dans l'industrie de fabrication du cuir, a fait une apparition remarquée à l'exposition. En tant que représentant commercial à l'étranger de la société chinoise de recherche et de développement de nouveaux matériaux zéolites pour cette technologie, le directeur d'iSuoChem a déclaré que les matériaux de tannage du cuir zéolite peuvent mieux résoudre le problème de pollution dans la technologie traditionnelle de tannage du cuir et permettre les micro-organismes naturels du cuir à mieux se décomposer, assurant ainsi la qualité de l'aspect, la souplesse et la couleur du cuir.

L'histoire du tannage du cuir

Le cuir le plus ancien a été fabriqué au soleil il y a des milliers d'années : les peaux fraîches étaient séchées au soleil, martelées dans la cervelle et la graisse d'animaux pour les ramollir, puis salées et fumées pour être conservées. Il faudra attendre 400 avant JC pour que les Égyptiens et les Hébreux découvrent que l'utilisation de méthodes de tannage pouvait rendre le cuir durable, imperméable et anti-corrosion : tremper le cuir dans des tanins végétaux, des sels minéraux ou des graisses animales pour modifier complètement sa structure protéique, puis teinture et autres étapes pour rendre le produit fini complètement déshydraté, avec des fibres serrées, durables et douces. Dans le processus moderne de transformation du cuir, le tannage est un processus important dans la fabrication du cuir et de la fourrure. Le processus physique et chimique de transformation des peaux brutes en cuir grâce à des agents de tannage est appelé tannage. C'est le processus de combinaison de la peau et des matériaux de tannage pour dénaturer la peau brute en cuir qui ne pourrit pas facilement. Un processus de traitement du cuir. Après ce processus, seul le cuir véritable contenu dans le cuir est laissé pour un traitement ultérieur.

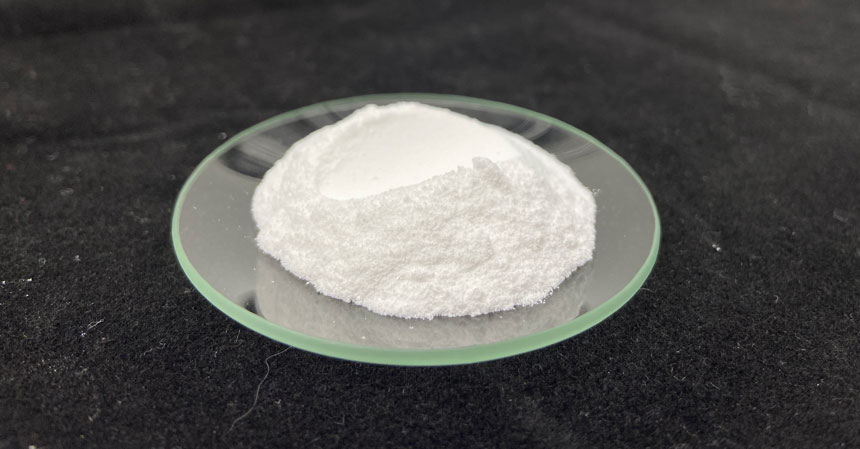

Agent de bronzage du cuir à base de zéolite

Quelle est la meilleure méthode de tannage pour le cuir ?

L'usine source d'iSuoChem s'est concentrée ces dernières années sur le développement d'une technologie de tannage du cuir respectueuse de l'environnement. Grâce à des expériences continues de recherche et de développement, elle a développé un agent de tannage du cuir de haute technologie à base de zéolite naturelle. Le personnel R&D de l'usine a déclaré que cette nouvelle génération de agent de bronzage zéolitique est un nouveau produit respectueux de l'environnement. Étant donné que le processus de tannage traditionnel est basé sur des agents de tannage au chrome et que le chrome hexavalent est évidemment toxique, il est facile de causer de graves dommages à l'environnement écologique et au corps humain lors de la production d'artisanat en cuir. L'utilisation de matériaux de tannage à la zéolite dans le processus de tannage du cuir peut remplacer efficacement les effets des agents de tannage au chrome traditionnels, prévenir efficacement la décomposition des peaux d'animaux brutes, contribuer à réduire l'impact sur l'environnement et à maintenir la qualité du cuir.

Avantages de la technologie de tannage du cuir à la zéolite

Le Directeur général d'iSuoChem a déclaré que cette nouvelle méthode de fabrication du cuir présente des avantages en termes de sécurité, de protection de l'environnement et d'excellentes performances du cuir. Étant donné que la zéolite possède de fortes propriétés d'adsorption et d'échange d'ions, l'utilisation d'agents de tannage zéolitiques peut augmenter l'absorption du cuir pendant le retannage et la teinture, réduire l'utilisation de matériaux chimiques dans ce processus et réduire la DCO (demande chimique en oxygène) dans les eaux usées. 38

De plus, les boues provenant du traitement des eaux usées du tannage à la zéolite et les résidus après les opérations de tannage sont sûrs et non polluants, et peuvent être utilisés pour la biodégradation et le compostage, favorisant ainsi l'ensemble du processus de tannage du cuir plus sûr et plus respectueux de l'environnement. Par rapport aux agents de tannage au chrome traditionnels, la particularité des agents de tannage du cuir à base de zéolite est qu'ils peuvent améliorer les avantages durables de l'industrie du cuir tout en offrant d'excellentes performances en cuir. Grâce à de nombreux tests, il a été prouvé que l'utilisation d'un agent de tannage zéolite peut donner au cuir une excellente étanchéité du grain, une excellente résistance à la lumière et une excellente résistance à la chaleur. Il peut être transformé en n'importe quel produit en cuir, des sacs à main aux coussins de siège de voiture, et la couleur des produits en cuir peut être plus vive, créant ainsi de nouvelles opportunités pour les fabricants et les marques de produits en cuir haut de gamme.

Quels sont les avantages de la technologie de tannage du cuir à la zéolite ?

Haute tension et bonne ténacité

L'utilisation d'un agent de bronzage du cuir zéolite peut donner au cuir une bonne ténacité, et la technologie de huilage et de calandrage est plus efficace.

Forte plasticité

La plasticité fait référence à la propriété du cuir qui peut conserver sa forme existante une fois son apparence modifiée. Après avoir utilisé un agent de bronzage à la zéolite, un cuir d'une bonne ténacité parfaitement compatible avec l'objet de stockage peut être fabriqué, et des vêtements et des chaussures adaptés à la condition physique de l'utilisateur peuvent être façonnés de manière flexible, afin que les utilisateurs puissent ressentir le confort apporté par le cuir.

Forte absorption d'eau

Par rapport au cuir tanné au chrome, le cuir zéolite a de meilleures performances d'absorption de l'eau et est facile à enlever les taches.

Doux, fin et flexible

Le cuir tanné à la zéolite étant doux, fin et agréable au toucher, il convient à la fabrication de produits près du corps.

Élastique et résistant à la chaleur

L'agent de bronzage du cuir zéolite est élastique, il n'est donc pas facile de se rayer ou de se déformer, et a une bonne résistance à la chaleur, ce qui peut être utilisé pour fabriquer des produits ayant des exigences de durabilité élevées.

L'apparence étonnante de la technologie de tannage du cuir à la zéolite au Tokyo Leather Show a attiré l'attention de nombreuses entreprises de cuir et instituts de recherche et développement bien connus à travers le monde. Certains hauts responsables de l'industrie ont même déclaré que cette technologie constituait une révolution innovante dans l'industrie mondiale du cuir et pourrait complètement changer le processus de tannage traditionnel.

En tant qu'alternative durable aux produits chimiques de tannage traditionnels, la technologie de tannage du cuir à la zéolite deviendra l'une des nombreuses voies entrelacées permettant à la zéolite de changer le monde. Avec la zéolite, nous ne sommes plus confinés au passé, mais nous avançons vers un avenir meilleur avec le cuir et bien d'autres industries..

Références

[1] Étude sur l'influence du temps de tannage au chrome de la machine à tanner le cuir sur les propriétés du cuir~[J]. Liu Haiteng ; Chen Guoping ; Chen Jie ; Sun Fangduo ; Yang Chengjie. Cuir de Chine, 2015(11)

[2] Discussion sur les caractéristiques et les progrès du mécanisme de tannage du cuir[J]. Zhou Hualong, Cheng Haiming, Tang Huazhao, Chen Jiali, Zhang Xinshen. Science et ingénierie du cuir, 2002(02)

[3] Étude sur le mécanisme d'adsorption et de liaison des fibres de collagène bronzées TWS/TWLZ sur des colorants directs/acides[D]. Yang Rui. Université des sciences et technologies du Shaanxi, 2022

[4] Chimie et technologie du cuir[M]. Liao Longli, éd. Presse scientifique. 2005